What Type of Rock Crusher Plant is Best Suited for Crushing Ore, Such as Copper or Iron Ore, in Indonesian Mining Operations?

- aimixindonesia5

- Apr 7

- 4 min read

Mining operations in Indonesia, especially those focused on extracting valuable ores like copper and iron, require efficient and durable machinery to handle the tough task of ore crushing. With the wide range of available rock crushers, it can be challenging to determine which is the best fit for specific mining needs. In this article, we will explore the types of rock crusher plant best suited for crushing ores such as copper and iron in Indonesia, offering valuable insights to help you make an informed decision for your mining operations.

Understanding the Challenges of Crushing Ore in Indonesia

Indonesia's mining industry has long been known for its rich deposits of copper, iron, and other valuable minerals. However, mining these ores presents several challenges. The hardness of the ores, the volume of material to be processed, and the need for consistent output all play a significant role in determining the best equipment for the job. Choosing the right stone crushing plant is critical to overcoming these obstacles and ensuring smooth, profitable mining operations.

Factors to Consider When Choosing a Rock Crusher Plant

Before diving into the specifics of different crusher types, it’s essential to understand the key factors that will influence your choice of rock crusher plant. These factors include the hardness of the ore, desired output size, and the overall efficiency of the equipment. In addition, the capacity of the crusher and its ability to handle varying material types are also crucial considerations. Understanding these aspects will help narrow down your options to the most suitable mesin penghancur for your specific needs.

1. Ore Hardness and Crushing Efficiency

One of the primary factors to consider when selecting a crusher is the hardness of the ore. Copper and iron ore are known for their high hardness, which means that the crusher needs to be robust enough to handle the tough material without compromising on efficiency. Jaw crushers are often the first choice for primary crushing in such cases due to their powerful crushing action. For more precise control over the particle size, cone crushers are a great option for secondary crushing.

2. Desired Output Size

Each mining operation has specific requirements for the size of the final crushed product. If you need finely crushed ore for further processing or smelting, a crusher with adjustable settings, like a cone crusher, might be the best option. On the other hand, if the goal is to produce larger chunks of ore, a jaw crusher could be more suitable for your needs.

3. Crusher Capacity

Capacity is another important factor when selecting a rock crusher plant. You’ll need to assess the volume of ore that needs to be processed daily and select a crusher that can handle the required throughput. For large-scale mining operations, a high-capacity crusher plant will be essential to keep up with the demand.

Types of Rock Crushers for Ore Crushing

Now that we have explored the key factors, let’s delve into the different types of rock crushers that are well-suited for crushing copper and iron ore in Indonesia’s mining industry. Each type of crusher has its unique advantages, making them better suited for specific applications.

1. Jaw Crushers

Jaw crushers are commonly used as primary crushers in mining operations. They are known for their robust design and ability to handle large chunks of ore. In the case of copper and iron ore, jaw crushers effectively break down the material into smaller, manageable sizes. They are highly versatile and can handle a wide range of material types, including very hard ores. If you’re looking for a machine that provides consistent results in the first stage of crushing, a jaw crusher is a solid choice.

2. Cone Crushers

After the initial crushing stage, cone crushers are often used for secondary and tertiary crushing. They are highly effective in producing finer particles and achieving precise control over the output size. For Indonesian mining operations dealing with copper and iron ore, cone crushers can significantly improve efficiency by ensuring a consistent and uniform product. With their adjustable settings, they offer flexibility in meeting varying output requirements.

3. Impact Crushers

While jaw and cone crushers are effective for primary and secondary crushing, impact crushers can be highly beneficial for finer crushing stages. They are ideal for producing a high percentage of fine material, which can be essential for downstream processes such as milling or smelting. Although impact crushers are typically used for softer materials, with the right configuration, they can handle harder ores like copper and iron.

Which Crusher is Best for Your Mining Operation?

Choosing the right rock crusher plant depends on your mining operation's specific needs. If you are looking for a machine that can handle large volumes of ore efficiently, a jaw crusher or cone crusher will likely be your best bet. On the other hand, if you require finer crushing and a high-quality end product, an impact crusher may be more suitable. For optimal performance, it is often recommended to use a combination of crushers to handle different stages of the crushing process.

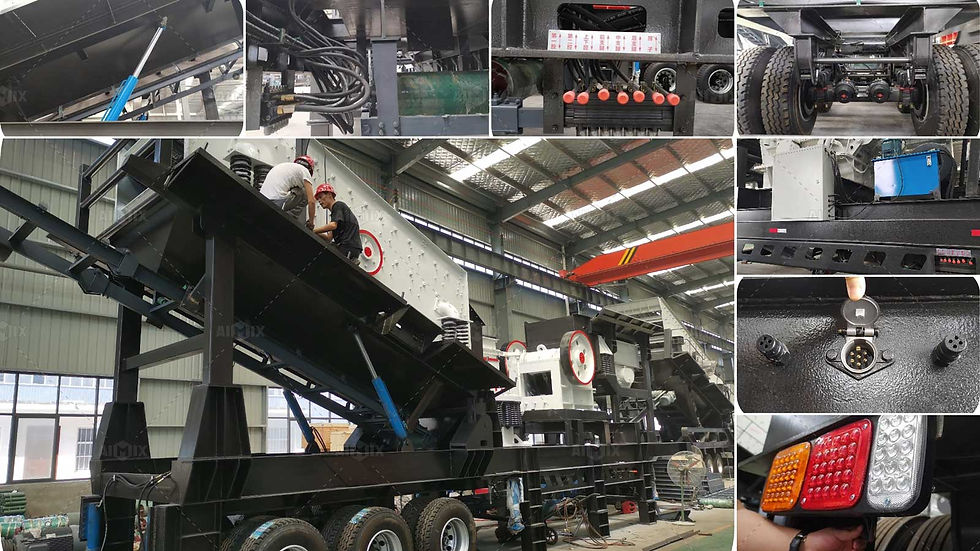

Why Choose AIMIX for Your Mining Crusher Needs?

When it comes to sourcing high-quality rock crushers for Indonesian mining operations, AIMIX offers a wide range of durable and efficient equipment designed to meet the demands of copper and iron ore crushing. AIMIX's crushers are known for their robust construction, high efficiency, and low maintenance requirements, making them a trusted choice for mining companies in Indonesia.

With a focus on customer satisfaction, AIMIX offers tailored solutions to ensure that your mining operations run smoothly and profitably. Whether you need a jaw crusher, cone crusher, or impact crusher, AIMIX can provide the perfect match for your requirements.

Conclusion: Invest in the Right Crusher for Your Mining Operation

Choosing the right rock crusher plant for crushing copper or iron ore in Indonesia is crucial to the success of your mining operations. By considering factors such as ore hardness, output size, and crusher capacity, you can make an informed decision on the best equipment for your needs. Remember, a combination of crushers may offer the best solution for a variety of crushing stages. AIMIX is here to provide high-quality, durable crushers to meet the unique needs of your mining operation. Don’t settle for less—invest in the right crusher to ensure efficient, cost-effective, and successful mining operations.