Which Crusher Configuration Is Best for Producing Cubical 5–20 mm Basalt Aggregate for Asphalt Mixing Plants?

- aimixindonesia5

- Oct 29

- 3 min read

When producing basalt aggregates for asphalt mixing plants, achieving a cubical particle shape between 5–20 mm is crucial. The shape affects not only the asphalt mixture’s strength and stability but also the final pavement’s durability. Many customers often ask: “Which crusher configuration—jaw + cone + VSI—is best for this purpose?” In this post, I’ll analyze each stage of crushing and explain why a combination of these mesin crushers is ideal for producing high-quality cubical basalt aggregate.

Understanding the Characteristics of Basalt and Asphalt Requirements

Basalt is a hard, dense, and highly abrasive rock. It offers excellent strength and wear resistance, making it perfect for asphalt production. However, its hardness also makes crushing more challenging. Asphalt plants, on the other hand, require aggregates with cubical shapes and consistent gradation. Angular and flaky particles reduce asphalt bonding, leading to weak pavement structures.

Therefore, to produce suitable basalt aggregates for asphalt, the crushing configuration must ensure not only proper particle size but also good shape and minimal fines.

Typical Crushing Process for Basalt Aggregate Production

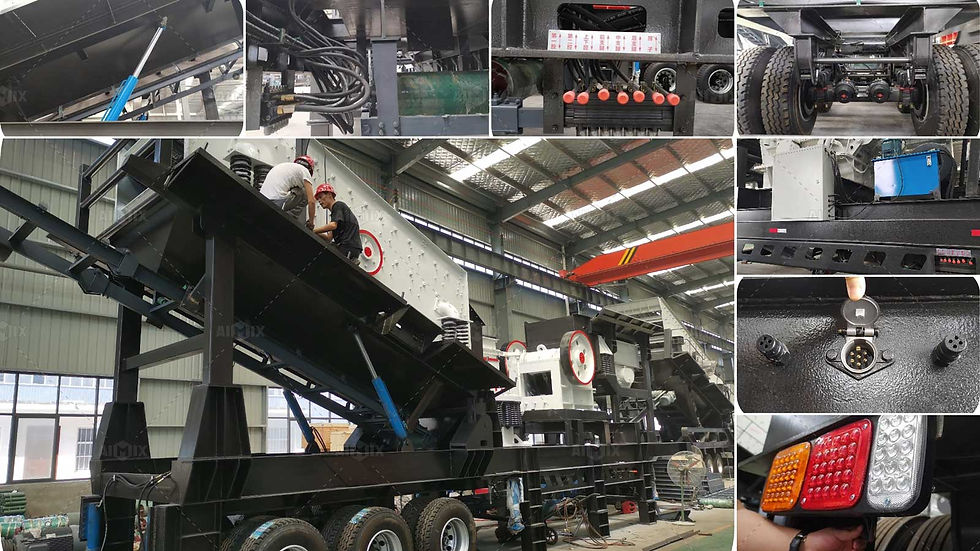

In most basalt crushing lines, a three-stage process is used: coarse, medium, and fine crushing. Each crusher type plays a different role. Let’s look at how a jaw crusher, cone crusher, and VSI crusher work together to deliver ideal 5–20 mm cubical aggregates.

Jaw Crusher – Reliable Primary Crushing

The jaw crusher for sale handles the coarse crushing stage. It reduces the large basalt rocks (usually below 500 mm) into smaller pieces, typically around 100–150 mm. Its simple structure and strong compressive power make it ideal for the first step. However, the product shape from a jaw crusher is often elongated, so it requires further shaping in the next stages.

Cone Crusher – Efficient Secondary Crushing

The cone crusher takes over the medium crushing stage. It processes the 100–150 mm material into smaller, well-graded stones, often between 20–40 mm. The cone crusher provides better shape control than a jaw crusher and maintains high efficiency. Yet, the aggregate may still have some flat or needle-like particles, which can affect asphalt quality. This is where the VSI crusher becomes important.

VSI Crusher – Key to Cubical Final Shape

The Vertical Shaft Impact (VSI) crusher is the final shaping machine. It uses the rock-on-rock crushing principle, where stones collide at high speed, producing well-rounded and cubical particles. This stage is critical for asphalt aggregate production. The VSI crusher not only improves shape but also helps control fines content, ensuring that 5–20 mm basalt aggregates meet strict asphalt plant standards.

Why the Jaw + Cone + VSI Configuration Works Best

Each crusher type has its strengths, but combining them ensures balance among capacity, shape, and efficiency. The jaw crusher provides a strong start, the cone crusher refines the gradation, and the VSI perfects the shape. Together, they form a complete and efficient solution for producing premium basalt aggregates.

In addition, this configuration reduces wear on each individual machine, extends service life, and minimizes downtime. For asphalt mixing plant owners, this means a stable supply of cubical aggregates with consistent quality—essential for producing durable asphalt mixtures.

Practical Considerations for Selecting the Configuration

When designing your basalt crushing line, consider several factors: raw material hardness, feed size, desired output size, and capacity. For example, if your asphalt plant requires mainly 5–20 mm aggregate, a configuration of jaw + cone + VSI with adjustable screening can help control the output precisely.

Moreover, pay attention to operating costs. While adding a VSI stage increases investment, it brings long-term benefits by improving aggregate shape and reducing asphalt consumption. This trade-off is especially worthwhile for contractors who need to meet strict pavement standards or serve high-end road projects.

Transitioning from Theory to Real-World Performance

In real-world projects, this configuration has proven effective in many basalt crushing sites. For example, in Indonesia, contractors producing asphalt for highways often choose jaw + cone + VSI setups because of the demanding quality standards. The final aggregates show excellent shape, good adhesion with bitumen, and longer pavement life.

In short, this combination ensures high performance under various working conditions, whether for municipal roads, expressways, or airport runways.

Choose a Reliable Partner for Your Crushing Solution

Selecting the right equipment is just the beginning. You also need a trusted supplier who can provide complete design, local service, and after-sales support. I provide customized basalt crushing solutions—including layout design, installation, and maintenance services—tailored to local asphalt production needs. With local offices and engineers in Indonesia, we can offer on-site assistance and fast technical support.

If you’re planning to set up a crushing line for basalt aggregate production or want to improve your current asphalt material quality, feel free to contact me. I’ll help you select the most efficient configuration to produce cubical 5–20 mm aggregates for your asphalt mixing plants.

Contact me today to discuss your basalt crushing needs and find the most suitable solution for your project.